Impact on BC’s forest products sector

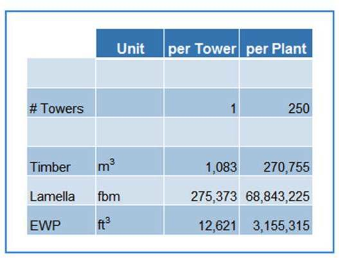

Timber wind turbine support towers made with materials such as cross-laminated timber (CLT) panels, for example, manufactured from local lumber, sustainably harvested from BC’s forests, would present a significant socio-economic opportunity for forestry-based regions. An 80-metre support tower made entirely of CLT would require more than 1,000 cubic metres of timber, 275,000 board feet of lumber and more than 12,000 square feet of 12-inch thick CLT panels. A moderately-sized engineered wood tower plant capable of producing 250 towers would utilize about 270,000 cubic metres of timber, about half of a moderately sized sawmill’s annual production (about 70 million board feet).

In addition, some of the most promising wind sites in North America are in northeastern BC. This large, emerging market is close to the fibre source, providing an excellent basis for a northern wooden tower manufacturing facility, as more than 3 million cubic feet of engineered wood would be required.

Much of BC’s lodge pole pine population has been affected by the mountain pine beetle, much of it in regions close to the best wind energy sites. Testing at UBC’s Centre for Advanced Wood Products has shown that solid wood panels made from MPB-affected pine have performed well in integrity testing, so towers could be sourced and built from plants in the BC Interior. In addition, since the boards making up the panels can be finger-jointed, lower-cost, short pieces that are the “fall-down” from dimension lumber manufacturing can be used.

Much of BC’s lodge pole pine population has been affected by the mountain pine beetle, much of it in regions close to the best wind energy sites. Testing at UBC’s Centre for Advanced Wood Products has shown that solid wood panels made from MPB-affected pine have performed well in integrity testing, so towers could be sourced and built from plants in the BC Interior. In addition, since the boards making up the panels can be finger-jointed, lower-cost, short pieces that are the “fall-down” from dimension lumber manufacturing can be used.